LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleMcDonough has recently begun work on a new AutoMAXX resaw system, a revolutionary machine that re-imagines what a resaw can do. The AutoMAXX system combines physical controls with a visual operator interface, high-quality digital imaging and optimization to maximize yield of grade and input.

The AutoMAXX comes with complete automation of turning, fence sets, gap control and feeding that allows the operator to focus on cutting decisions and grade. This system increases yield of your highest-grade products, and increased line counts at equivalent feed speeds.

Requiring only one grader/operator, optimum saw feed speeds will reduce saw fatigue while increasing saw capacity. The PLC controlled turning, feeding and cant spacing will keep gaps to a minimum, even when changing sets.

McDonough invented the Travelling Bed Feed Resaw, now known as the Linebar Resaw, that revolutionized the sawmill industry. With the new AutoMAXX resaw system, McDonough is once again advancing resaw technology and capability.

We would like to introduce you to our newest forestry rep for our northern West Virginia territory, D Jay Miller. D Jay lives in Elkins, WV with his wife of 20 years, Krista and has two kids ages 16 and 10. D Jay worked in the trucking industry for 15 years as a freight broker and also had 30 trucks that served the oil field industry. Prior to that he worked for Reckart as an equipment salesman. We are excited to welcome D Jay to our Ricer family of employees and wish him a ton of success! You can reach D Jay at 304-704-6916 or email him at djay.miller@ricerequipment.com.

New MB100 SlabMizer Produces Smooth Slabs

Wood-Mizer introduces the MB100 SlabMizer Slab Flattening Mill designed for woodworkers who want high-quality flattened wood slabs up to 36” wide with minimal labor. Built in the USA, the MB100 joins the Wood-Mizer slab flattening mill product range for efficiently surfacing and flattening wood slabs, boards, burls, cookies, and other wide material.

Compared to a traditional router or planer, the MB100 SlabMizer flattens material up to 36” wide and 8” thick in less time using a 3HP electric 5" cutting head equipped with five 4-sided carbide knives. For wider material, Wood-Mizer offers the MB200 SlabMizer capable of processing material up to 56” or 72” wide.

To flatten material, the cutter head is moved side-to-side with a handle and secured with pre-set notches. With a manual push feed bar, the cutter head is moved forward/reverse until the material features the smooth finish required with each pass. Cutting depth is adjusted from 1/64” to 1/8” in 1/64” increments by a hand crank located on the top of the cutter head.

The MB100 requires at least one LT15WIDE bed section sold separately from Wood-Mizer to operate or can be added to the popular Wood-Mizer LT15WIDE portable sawmill bed to optimize processing space. For longer capacity, unlimited 6’ 8” modular bed sections can be added to extend the material length. Two adjustable clamps to secure material on the bed and four bed spacers are included with each MB100 Slab Flattening Mill.

MB100 SlabMizer Slab Flattening Mill Features

· 36" max material width and 8” max thickness

· 5,500 RPM 5” cutter head with five 4-sided carbide knives

· One or more LT15WIDE bed sections required

· Can be added to Wood-Mizer LT15WIDE portable sawmill

· Built in the USA

“Wood-Mizer is committed to providing our customers with the equipment necessary to process material from forest to final form,” said Russell Fite, Wood-Mizer North America Sales Director. “The MB100 SlabMizer is our lowest priced slab flattening mill that satisfies the needs of hobbyists and professionals producing high-value finished slabs while reducing manual labor.”

Starting at $9,995 USD, the MB100 SlabMizer is now available to order in North America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, woodworking equipment, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

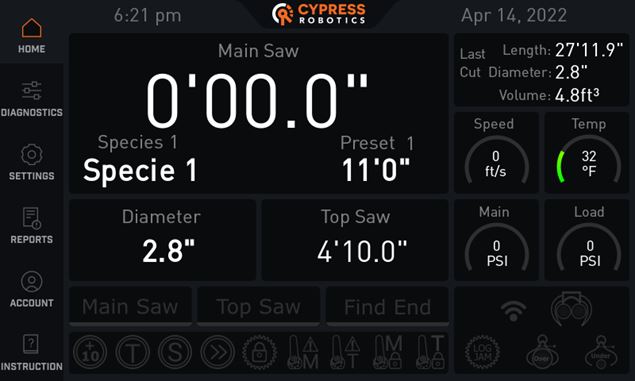

Axis Forestry introduces the Gen5 Cypress Robotics Controller to operate all makes and models of processor heads. The Cypress Robotics Controller is designed and manufactured in Canada and incorporates feedback from hundreds of logging contractors. Loggers want a tree processor controller that is simple to install, reliable, easy to use and affordable- the Cypress Robotics Controller delivers all of this and more!

The Cypress Robotics Controller matches powerful and modern software technology with tough and reliable hardware, creating an easy to navigate touch-screen operating system. The Cypress software is intuitive and easy to understand so operators do not require training and are operational within minutes. With simplified hardware and comprehensive video tutorials, the Cypress Robotics Controller is a breeze to install and configure for optimal operations. The Cypress Robotics Controller also includes a suite of onboard self-diagnostic tools and is well-supported by the team at Axis Forestry. Axis technicians can remotely log in to provide diagnostic support and software updates through a Bluetooth connection- no cell service required!

The Cypress Robotics Controller can be retrofit on to any existing brand of tree processor and offered at a lower price point than traditional tree processor control systems. For a limited time, Axis Forestry will buy back old computer control systems for a $3,500 dollar credit towards a new Cypress Robotics Controller. To find out more, visit www.axisforestry.com or call 360-656-6421.

About Axis Forestry:

Axis Forestry is a forestry manufacturing company founded in 2010, created to serve forestry logging contractors worldwide by providing replacement parts, new equipment, new modern computer technology, and strong customer support to optimize logging operations. Axis Forestry is an OEM manufacturer of the Rebel brand of Tree Processors and Cypress Robotics Controllers. Axis Forestry has two locations, one in Kamloops BC, Canada and one in Ferndale, Washington.

In traditional fashion, the 84th Annual Oregon Logging Conference was held at the Lane Event Center and Fairgrounds in Eugene, February 24 – 26, 2022.

After celebrating the OLC in a scaled down version in 2021, many positive comments were made this year about being able to gather in-person.

“After the last two years, the best thing about this year is getting back together,” 2021/2022 OLC President Scott Melcher, of Melcher Logging in Sweet Home said. “I think that’s one of the strengths, the connectivity and the bonds that we have,” he added. “We might be competing against each other one day, and the next we’re sitting down talking and sharing ideas.”

Conference Manager Rikki Wellman said this year, there was more equipment on display outdoors compared to previous years. And while paid registration was slightly down this year, there was no dip in attendance with many industry professionals and members of the public participating in the OLC

“The last couple of years have been a challenge for all of us,” Conference Manager Rikki Wellman said. “Being together in 2022 helped restore the traditions of the OLC,” she added, “seeing our friends faces again and enjoying the camaraderie.”

2022 Keynote speaker – Blake Manley

Keynote speaker Blake Manley shared his incite and success in engaging and encouraging young men and women to consider careers in the logging and forestry industries. Manly is a Natural Resources teacher at Sweet Home High School, creator of the Manley Jobs career video YouTube series, Chair of the Oregon Natural Resources Teachers Association, and a logger.

Manley was also the speaker at the annual Desserts for Dreams luncheon, where he suggested ways to continue reaching out to young women and men with information about the logging and other natural resource industries. The charity selected by Oregon Logging Conference First Lady Wendi Melcher, to receive proceeds from the event was the Sweet Home High School Forestry Club, which will receive more than $10,000.

Seminars and Panel Discussions

Topics of current interest were discussed at the 84th Annual Oregon Logging Conference, while many of those attending earned Professional Logger credits to stay certified and up to date on several issues. Topics addressed included:

- The Private Forest Accord

- A changing labor force (Better Ideas/New Technology in Logging)

- Reducing worker stress and fatigue from day-to-day equipment operation

- Your voice, your vote counts

- Log damage caused by modern processing equipment

- Oregon and Washington Forest Practices Act seminars

“The Oregon Logging Conference is packed with unique opportunities for forestry and natural resource professionals to network and learn more about their trades,” said Rikki Wellman, OLC Manager.

Oregon Logging Conference Foundation Auction

$28,000 was raised during the Thursday and Friday auction at the Oregon Logging Conference. This money will be used for scholarships and other educational endeavors, including the above-mentioned Future Forestry Workers Career Day.

Log Loader Competition

You’ll recognize the winner’s names in this popular competition.

First place was Zane Bryant of Bryant Logging in Beaver Creek, OR with a time of 2:57:09. Second place was Justin Jackola of Rice Logging in Sweet Home, OR with a time 3:34:16 and third place was Bryan Chipps of Green Diamond Resource Company in Korbel, CA with a time of 3:42:17. This popular outdoor event tests the skills of log loader operators, as they demonstrate speed, skill, and efficiency. Operating a Link-Belt log loader, contestants have seven minutes to stack log blocks end-to-end, matching numbers or colors on predetermined marks on the ground.

85th Annual Oregon Logging Conference

The dates are set for the 85th Annual Oregon Logging Conference. Plan to attend the OLC February 23 - 25, 2023 at the Lane Event Center and Fairgrounds in Eugene, OR.

For more information, contact Rikki Wellman, OLC Manager, (541) 954-2477 or Mary Bullwinkel, Media/Communications Coordinator – (707) 601-6533.

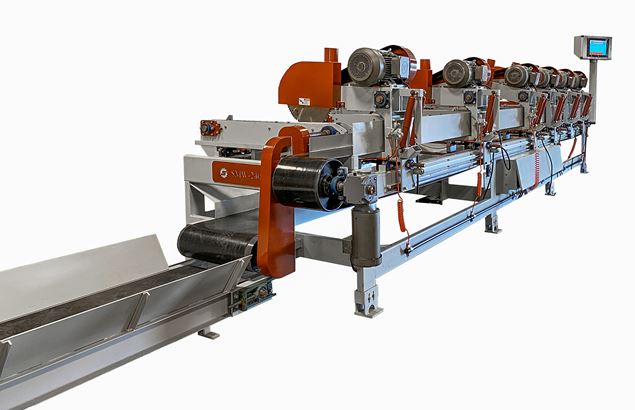

Make changeovers in UNDER 5 MINUTES with SMW’s new SMW-192 or SMW-240 multihead trim saw! Standard 5 or 6 head multi-head trim saw featuring an optional digital readout screen. The digital readout is a digital screen SMW mounts to the back of the saw to assist with head positioning. As the operator moves each head, while making a changeover, the digital readout will display the exact measurement the head is at. This cuts changeover times from 20-30 mins down to under 5 minutes. Save time, increase volume, and profitability!

About Smith Machine Worx

Smith Machine Worx brings over 25 years of experience to your floor. American ingenuity and hard work combined with trust and honest service makes us your best bet to operate efficiently. Specializing in automation consulting and process machinery company. Using their success in the wood products industry as a part of the Smith Family Companies, Smith Machine Worx is taking their expertise in machine systems and equipment to companies in need of system improvements.

Call us at 205-528-8644 or visit our website at www.smithmachineworx.com today to find out how our SMW-192 or SMW-240 Multihead Trimsaw can speed up your production!

The stage is set. 2023 will mark a new tour for the successful Forest Products Machinery & Equipment EXPO, bringing the show for the first time ever to Nashville, TN. The Music City Center is Nashville's convention center located in the heart of downtown. The facility has the technology and equipment to ensure all needs are met for both exhibitors and attendees. In the evening, enjoy downtown Nashville, surrounded by numerous hotels, restaurants and entertainment venues. Located adjacent to the Bridgestone Arena and the Country Music Hall of Fame, there is plenty to do after an exciting day on the trade show floor.

The Forest Products Machinery & Equipment EXPO is the place to connect with key players, explore opportunities and generate new business. Through lead generation and relationship building, the forest products manufacturing industry is well represented. Connect with hundreds of lumber manufacturers to build relationships and brand awareness. Connect with key decision makers and display the latest in wood processing technologies and services. Take advantage of EXPO Sponsorships to set your company apart and gain exposure with attendees through a variety of opportunities leading up to and during the show. Exhibiting at EXPO allows you to discover new business opportunities through generating leads and enriching existing relationships.

Stay tuned for more information about Nashville exhibiting and sponsorship opportunities coming this spring at the SFPA Board of Directors meeting, March 17, 2022.

EXPO Richmond 2022 May 20th – 21st, 2022

America’s leading trade show for the forest products industry, featuring 300+ indoor and outdoor exhibits, educational sessions, and equipment demos.

Registration is now open exporichmond.com

804-737-5625

EXPO RICHMOND 2022

PO Box 160 | Sandston, VA 23150

Wood-Mizer introduces the MP180 Jointer Planer Moulder as a three-in-one woodworking machine able to produce tongue and groove paneling, shiplap, trim, and more. Starting at $7,995 USD, the MP180 takes the versatile functionality of the Wood-Mizer MP160 Jointer/Planer and adds a vertical side cutter head to the planer table. The MP180 joins the established Wood-Mizer range of woodworking products that includes jointer/planers, two-sided planer/moulders, four-sided planer/moulders, slab flattening machines, dust collection systems, planer blades, moulder knives, and more.

Similar to the MP160 Jointer/Planer, the MP180 efficiently shares one horizontal cutter between two cast iron tables to produce straight-edged boards with the top jointer table and evenly planed boards with the bottom planer table. Switching between jointing and planing is done easily by moving the board from one table to the other without needing to adjust the table or stop the cutter or extractor. When jointing boards on the upper table, an adjustable board fence tilts up to 45° and locks into place for angled boards.

In addition, the MP180 features one vertical side cutter that can be fitted with moulding profile knives. The vertical side cutter moulds material on one side with each pass through the bottom planer table. With the MP180, moulding material on two sides for profiles like tongue and groove can be completed in only two passes. When planing and moulding boards on the bottom table, two power feed rollers move the board through the horizontal cutter and vertical side cutter at a variable speed.

MP180 Jointer Planer Moulder Features

- Starting at $7,995 USD

- 3-in-1 jointer, planer, moulder combo

- Switch between jointing, planing, and moulding without adjusting the table or stopping the cutters

- Jointing capacity: 9" wide

- Adjustable jointer board fence up to 45°

- 1-sided planing capacity: 16" wide x 9-1/2" high

- 2-sided planing/moulding capacity: 12" wide x 2" high (4” high with optional side cutter head)

- 6-39 fpm variable feed for planing and moulding

- Heavy-duty cast iron tables and sheet steel chassis

- 240V 60Hz 1-phase or 3-phase electric power

“Wood-Mizer is dedicated to providing the best-in-class equipment for sawmillers and woodworkers throughout the world,” said John Smith, Wood-Mizer CEO. “The MP180 is a unique and cost-effective machine that produces the professional results of a jointer, planer, and moulder in one compact footprint.”

The MP180 Jointer Planer Moulder ships on a pallet and requires minimal assembly. Planer blades, moulder knives, and dust collection systems are also available from Wood-Mizer. The MP180 Jointer Planer Moulder is now available to order worldwide. For more information, visit woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, woodworking equipment, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Cleereman Industries, one of the leading manufacturers of top-quality sawmill equipment, is proud to announce the purchase of CPF Manufacturing in Crandon Wi. CPF; a fully equipped and staffed, fabricating and machining facility. Paul Cleereman, VP of Cleereman Industries, said this new facility will be for the Cleereman Edger and Bandmill divisions along with some other Cleereman product lines. With our new Edger line and building bandmills for our Lumber-Pro’s this purchase made sense. The 20,000 square foot facility is equipped with overhead cranes and has large machining capabilities that include three large boring bars, turning centers, drill presses, etc. as well as a full range of large welding positioners and several welders. The facility also has a large drive through media blast cabinet that is used for complete paint and rust removal of large equipment. This will be extremely useful when rebuilding Cleereman equipment for customers.

The newly acquired facility had a long-standing business relationship with Cleereman Industries for over 30 years and did a lot of machine work for Cleereman Industries including our new Edger Boxes. Due to the unexpected death of Larry Colburn one of the owners and a good friend of Cleereman Industries the opportunity arose to purchase the facility and create a stable and ongoing employment for all of the employees and the Crandon community. As well as providing a turn-key solution to Cleereman Industries for increasing demand for not only our Edger line but all lines of Cleereman equipment.

The Crandon location also allows us to draw from a different talent pool of employees from a different region then our current Newald facility. Cleereman looks forward to providing Crandon and the surrounding communities with great employment opportunities.

For complete details contact:

Cleereman Industries

www.cleereman.com ·

Wood-Mizer introduces pallet recycling systems designed to dismantle, trim, and recycle pallets all-in-line. Wood-Mizer pallet recycling systems combine world-class built in the USA pallet recycling equipment with efficient and configurable material handling equipment. In addition to complete systems, Wood-Mizer offers standalone equipment for the pallet industry including sawmills, horizontal resaws, gang saws, pallet dismantling bandsaws, power feed trim saws, and material handling.

With the ability to create configurable systems for a variety of operations, Wood-Mizer pallet recycling systems include a combination of pallet dismantlers, material handling equipment, and pallet trim saws. The Pallet Hawg® PD200 Pallet Dismantler dismantles pallets into boards and stringers for additional processing and features 60”, 66”, 72”, 84”, or 96” wide options with rear or center drop table options. Belted conveyors and cross transfer decks transport material for staging or processing and include configurable options such as length, height, and incline. The PC200 Pallet Trim Saw trims boards and stringers for further processing or assembly.

“Wood-Mizer is dedicated to providing the best-in-class equipment for a variety of timber and wood processing needs throughout the world,” said Brad Kirkaldy, Wood-Mizer Pallet Recycling Product Manager. “The addition of our pallet recycling systems provide optimized equipment solutions for pallet businesses that are backed by our established network of service and support.”

Wood-Mizer pallet recycling systems are now available in North America. Contact your local Wood-Mizer representative for a layout and quote. For more information, visit https://woodmizer.com.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a global-leading sawmill and woodworking equipment manufacturer with a strong legacy from its innovative sawmilling products. From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including portable and industrial sawmills, resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment. For more than 40 years, Wood-Mizer remains committed to serving sawmilling and woodworking hobbyists and professionals all over the world throughout an established and growing distribution network. Visit woodmizer.com for more information.

|

.jpg)

.gif)