LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleCompanies are lining up to select their preferences for exhibit space at EXPO 2015 – the 33rd Forest Products Machinery & Equipment Exposition – to be held June 10-12 at Atlanta’s Georgia World Congress Center. Exhibitor sales kits have been mailed to nearly 1,000 contacts in the wood products industry.

Sponsored and conducted by the Southern Forest Products Association (SFPA) since 1950, this event has traditionally included many of the biggest names in the business displaying everything from sawmill machinery to materials handling equipment, attracting key representatives from the nation’s largest wood products manufacturers.

“The new, larger floor plan is generating increased interest in our event,” reports SFPA’s exposition director Eric Gee. “And the addition of an outdoor exhibit and demonstration area will provide opportunities for more companies to participate,” he adds.

Many exhibitors from the 2013 show have already expressed plans to expand their displays for the 2015 event. With indications of a housing market turnaround finally taking a firm hold, next year’s Expo is the best place to be for companies wanting to showcase equipment, products and services for the wood industry. Expo 2013 featured 154 exhibitors, with a total attendance of nearly 2,000.

For more information about EXPO 2015, visit www.sfpaexpo.com. To receive a sales kit and exhibit space application, contact Eric Gee at 504/443-4464 (option 3), or e-mail him at egee@sfpa.org. Follow the show on Twitter: @forestprodexpo.

LumbermenOnline.com has become the leading buy/sell website for logging, sawmill, pallet, biomass, woodworking, firewood and transportation equipment by utilizing cutting edge technologies to work for lumbermen worldwide. The most recent of those technologies is a mobile website designed to make finding new and used equipment for sale, information and video from the leading manufacturers, upcoming auctions and of course, industry news, quick and simple.

The new mobile site automatically identifies when you are accessing http://mobile.LumbermenOnline.com with a smartphone or tablet and seamlessly shifts to the mobile version. Visitors will have the option to view the full site from a simple to use “hamburger” menu located on the top of all mobile pages.

Vice President of Operations, Noah Carr, noted that with an average of 1,000 visitors daily, 40% of which are using mobile devices, the new mobile site would prove hugely beneficial for buyers and sellers alike. He added that this new capacity will allow also LumbermenOnline to create mobile sites for our customers at a fraction of what many, non-forest industry website companies are charging.

Bookmark www.LumbermenOnline.com today, to quickly stay connected with the forest industry anywhere on-the-go!

Aiken, SC – Hutto Wood Products has added another great option in their line of shaving mills, the HU16 Block Shaver. This compact mill is designed to focus on cut-offs, loose ends, and other scrap wood material ranging from 1 ½” up to 4” regardless of species. Like all of Hutto’s mills, the HU16 Block Shaver is built to last, hands free, 100% ready to run when it arrives and most importantly – affordable. If you are tired of seeing blocks and other scrap material pile up – the HU16 Block Shaver is for you!

Patrick Hutto, owner of Hutto Wood Products, says his goal is to come out with a new, innovative product each year. Last year the Hutto Mini Mill was a great success, this year the Hutto Block Shaver expects to do the same. To see the new Block Shaver, all of Hutto’s equipment options, and to stay connected with what’s next, visit www.HWPShavers.com or call 803-564-7173 today!

Wood-Mizer LLC, the world’s leading sawmill manufacturer, introduces the LT15WIDE manual sawmill – a mill that expands the capabilities of the already versatile LT15 sawmill. Engineered to saw wider logs economically, the LT15WIDE will join Wood-Mizer’s industry leading line of portable sawmill equipment.

With an 8-inch wider cut capacity than the standard LT15 model, the LT15WIDE is designed for sawyers looking to maximize cutting capabilities while minimizing investment. In comparison to the standard LT15, the LT15WIDE provides a heavier & wider bed frame, taller & heavier head supports and a higher production rating of up to 375 board feet per hour.

Main Features

36” maximum log diameter

17’ 8” maximum log length, no limit with bed extensions

25HP gas, 17HP diesel, 10HP electric

power options

Six reinforced side supports with rollers

“The LT15WIDE will give you the versatility of our LT15 sawmill with the cutting capacity of a larger mill,” said Wood-Mizer’s COO, Darryl Floyd. “The LT15WIDE features a healthy amount of upgrades suitable for maximum production from a manual sawmill.”

The LT15WIDE uses Wood-Mizer thin-kerf blade technology to reduce waste and maximize yield and is currently available for purchase. Wood-Mizer will continue to offer the standard LT15 sawmill, the LT15WIDE will be offered as an additional sawmill model option.

###

As the leading manufacturer of portable band sawmills for more than 30 years, Wood-Mizer offers an extensive line of portable and industrial sawmill equipment. The company supports its equipment with legendary customer service, blades, and blade maintenance equipment. For more information about Wood-Mizer, call 800.553.0182 or visit www.woodmizer.com.

The Kentucky Forest Industries Association (KFIA) will hold its 49th Annual Meeting on April 2 - 4, 2014 at The Brown Hotel in Downtown Louisville, Kentucky. The association plans to host over 400 company representatives from throughout the region. There will be a variety of discussions and activities to enjoy during the event. A number of opportunities will be made available for attendees to gather and discuss current issues, and meet with customers both new and old. The meeting will get underway with a golf outing at the Oxmoor Country Club Golf Course in Louisville, Kentucky and a tour of the Evan Williams Bourbon Experience.

The exhibit area will be open throughout the meeting and the Tree Farm Awards Luncheon will recognize outstanding individuals for their achievements in the forest industry community.

Speakers will include Joe Collins, from the University of Kentucky Department of Entomology will provide an update on the Emerald Ash Borer and Thousand Cankers Disease plaguing the industry and a presentation will be made by Matt Bynum with Louisville Slugger bats to explain how the ash borer is affecting their wood procurement strategies. Chris Morris, Master Distiller from Woodford Reserve will also provide an update on recent growth in the bourbon and stave markets. An expert panel will be debating the proposed Hardwood Check-off and it’s affect on the industry.

For more information on exhibiting or attending the 2014 Annual Meeting or KFIA programs and membership, please call 502/695-3979, email michele@kfia.org or visit the website at www.kfia.org.

Mill Innovations and Design, the creators of the TS-4000 Tie Stacking System, have released their new TDA-1220 Mat Assembly System. This radical breakthrough will allow sawmills who produce cross ties and sell mat materials to capitalize on growing markets in crane mat, dragline mats, barge mats, pipeline mats, logging mats and rental mats for the construction, oil and gas exploration industries. The use of timbers in this market segment has grown exponentially. The new TDA-1220 Mat Drill, Trim & Assembly System is a complete and fully automated system with only two operators. Capable of producing forty mats in a single eight hour shift, from timbers 6” – 12” and up to 20’ long.

Maximize your profits by adding this simple to operate, self-contained, fully tested TDA-1220 Mat Assembly System to your sawmill operation today. For complete details contact Mill Innovations & Design at 330-567-3373 or visit www.MIDllc.com.

Eugene, Ore.- This past weekend, the Lane Country Events Centers and Fairgrounds saw the largest Oregon Logging Conference show since 2008, when the industry experienced an economic downturn. The attendance at the two and a half day show was estimated to be well over 5,000. The conference saw an increase in exhibitors and registered companies.

The Log Loader Competition was once again a must-see for attendees. The 5th Annual Log Loader Competition was held on Friday and Saturday of the 2014 conference. The results are as follows:

First Place - Ross Cribbs, Van Well Timber Co., Dallas, Oregon – Time of 3.38

Second Place – Zane Byrant, Michael Bryant Logging, Beaver Creek, Oregon – Time of 3.49

Third Place Trevor Rhea – Rose Logging Inc., Springfield, Oregon – Time of 4.02

The 2014 conference also featured the 2nd Annual Guess the Net Scale event. There were three attendees who guessed the correct board feet of 5,900. These three were put in a hat for drawing and the lucky winner was Alex Schryvers of Springfield, Ore.

Thank you to all attendees and exhibitors who contributed to the success of the 2014 conference.

The Oregon Logging Conference directors and staff are already anticipating next years show. The following board officers and staff will serve the OLC for 2014-2015:

• David Nygaard, Warrenton Fiber, Warrenton, OR., President

• Jeff Unger, Unger Logging, Reedsport, Ore., First Vice President

• Jeff Wimer, Logger Training Program, Oregon State University, Second Vice President

• Mike Randall, Swanson Bros Lumber Co., Noti, Ore., Treasurer

• Rikki Wellman, Oregon Logging Conference, Eugene, Ore., Conference Manager

The 2015 Oregon Logging Conference is scheduled for February 19, 20 and 21 at the Lane County Events Center and Fairgrounds in Eugene, Ore.

The 2015 Oregon Logging Conference will feature education seminars, exhibits on the latest technology in logging equipment, networking opportunities and the chance to earn professional logger credits. Details are available at the Oregon Logging Conference Web site, www.oregonloggingconference.com, or by calling 541-686-9191.

Contact: Rikki Wellman, Oregon Logging Conference, (541) 954-2477

The Executive Committees of the Southern Forest Products Association (SFPA) and Southeastern Lumber Manufacturers Association (SLMA) have announced plans to reactivate their joint promotional program under the Southern Pine Council (SPC) banner. SLMA Chairman Chris deMilliano of Steely Lumber Company and SFPA Chairman Joe Kusar of Tolleson Lumber Company made the announcement following SLMA’s recent Spring Meeting. The first priority of the SPC is to improve export markets for Southern Pine lumber.

The reactivated SPC will be managed by a Board of Directors, consisting of the respective SFPA and SLMA executive committees. Joe Kusar has been named chairman of the Southern Pine Council, with Chris deMilliano to serve as vice chairman. Bryan Smalley of SLMA has been named director of the Southern Pine Council.

“Both associations look forward to working as one voice for the global promotion of Southern Pine products,” stated Joe Kusar. “The Southern Pine Council is an established moniker and can serve our industry for additional areas of cooperation in the future,” he added.

“Working together, SLMA member producers can now more efficiently interact with importers and other customers overseas,” noted Chris deMilliano. “Online supplier listings will increase the availability of Southern Pine products worldwide,” he added.

For more than 30 years, SFPA has been a funded cooperator of the USDA’s Foreign Agricultural Service, operating under the American Softwoods banner. SFPA’s trade promotion programs include appearances at international trade fairs, trade missions to key markets and direct contact with importers. A network of overseas consultants services inquiries about Southern Pine products, offers trade barrier assistance and manages other activities in the field. Programs promoting Southern Pine are currently underway in Mexico, the Caribbean Basin and Latin America, South America, China, Japan, Korea, Southeast Asia, Europe, India, the Middle East and South Africa. A multilingual website – www.SouthernPineGlobal.com – provides a product locator and exporter directory to help importers source Southern Pine lumber from member suppliers. Publications in a dozen languages deliver facts on the proper specification and use of SP products.

The Southern Forest Products Association (SFPA) has announced that, for the fourth consecutive year, shipments of Southern Pine lumber recorded an increase from the previous year.

Shipments in 2013 totaled 15.026 billion board feet (Bbf), an increase of 5% over the volume shipped in 2012 (14.279 Bbf) and 27% above 2009 shipments (11.79 Bbf).

Tabulation of Southern Pine shipment totals is a cooperative effort with the Southern Pine Inspection Bureau (SPIB) and Timber Products Inspection (TP).

SFPA is a nonprofit trade association that has represented manufacturers of Southern Pine lumber since 1915.

Today, SFPA is the leading source of information about Southern Pine products for design-build professionals and consumers.

2900 Indiana Ave. Kenner, LA 70065 • 504/443-4464 FAX: 504/443-6612

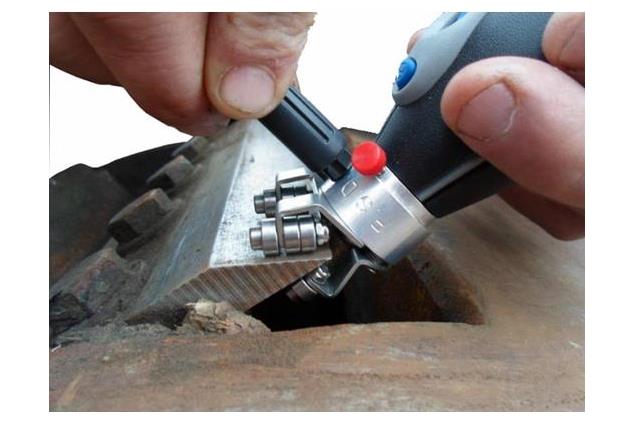

Winn, Mich. (March 6, 2014) – Morbark, Inc., a leading manufacturer of durable, high-performance wood waste reduction equipment for more than 50 years, is proud to announce that it has signed a contract with Precision Sharpening Devices Inc. to sell the Bevel Buddy™ Chipper Knife Sharpener through its authorized dealer network.

Since 1988 Precision Sharpening Devices, Inc., has been manufacturing counter grinding/back beveling equipment for knives used by a variety of industries, mostly for the pulp and paper, sawmill, plywood, and whole tree chipping markets.

The Bevel Buddy handheld sharpener allows the knives to be re-sharpened without needing to be removed from the machine. The knives can be re-sharpened this way two to three times, reducing customer downtime.

“The partnership between Morbark, Inc., and Precision Sharpening Devices, Inc., with their line of Bevel Buddy™ Chipper Knife Sharpeners will offer our customers a product that helps them operate their equipment at the highest levels of efficiency,” said Mark Mills, Precision Sharpening Devices, Inc. “The results are fuel savings, meeting production quotas, less down time, and greatly reducing their overall costs while maintaining a quality product and a safer work environment. Both parties view this as a ‘What’s best for the customer’ focus.”

“We’re always looking for ways to make our customers more productive, more efficient and more successful,” said John Foote, Morbark VP of Sales and Marketing. “Partnering with Precision Sharpening Devices, Inc., to offer the Bevel Buddy through our worldwide network of authorized Morbark dealers gives our customers easy access to another tool to help them be more productive, and ultimately, more successful.”

About Morbark:

Morbark, Inc., based in Winn, Mich., builds equipment that creates opportunities in the forestry, recycling, sawmill, bio-energy and tree care markets. Innovating and manufacturing durable, high-performance equipment for more than 50 years, Morbark offers a full line of whole tree and waste wood chippers, flails, brush chippers, horizontal and tub grinders, sawmill equipment, material handling systems and more. Morbark equipment helps customers harvest, process and convert wood and organic waste materials into valuable, useful and environmentally sound products.

Visit www.morbark.com, “Like” us on Facebook or subscribe to our YouTube channel.

Universal Machinery Sales has just introduced a new line of premium Steel Self- Dumping Hoppers for wood scrap applications. These Hoppers may be customized according to customer specifications. The '2-Yard' Model is a basic design, constructed with 1/8" steel plate. Dimensions for the '2-Yard' Hopper: width 54"; length 65"; height 48"; and depth 39-1/2". Standard Hopper sizes are '1-Yard', '2- Yard', and '3-Yard' load capacities. The Hoppers are equipped with forklift channels for improved mobility, and a 54" total reach provides increased load stabilization. The load may be locked in place, but the Hopper has a trip-lever for easy dumping.

For more information, Contact Mona Tracy at Universal Machinery: 855-298-8890

"If It's New, It's Here," proclaims the Association of Equipment Manufacturers of the CONEXPO/CON-AGG trade show, and Morbark® does not disappoint on that score. Morbark, Inc., a leading manufacturer of durable, high-performance wood waste reduction equipment for more than 50 years, will debut an exciting new product at this year's CONEXPO show.

Morbark partnered with its European dealer, OBMtec, to produce the Barracuda, a single-rotor, slow-speed shredder for markets outside of Europe. The Barracuda, developed by OBMtec and manufactured at Morbark's Winn, Mich., factory, offers a universal solution for industrial, C&D, wood and other waste streams, providing a high-quality end product with low operating, maintenance and fuel costs.

"Adding the Barracuda shredder to our industrial product line allows our customers to easily expand their capabilities in C&D and industrial waste reduction," said John Foote, Morbark VP of Sales and Marketing. "Our ultimate goal is to make our customers successful, so the machine was designed for versatility and ease of maintenance. With high fuel efficiency and low operating and maintenance costs, combined with the versatility to process a wide variety of materials, the Barracuda provides exceptional value to our recycling customers."

Key benefits of the Barracuda include:

• Ease of maintenance: The Barracuda is designed with serviceability in mind. All daily maintenance, such as cleaning the air filter, and checking and changing fluids, can be done while standing at ground level.

• Versatility: The Barracuda's ground-level adjustment door allows you to adjust grates in as little as 2 minutes, reducing downtime and increasing productivity. The counter knives can be repositioned to 5 different heights-higher for waste wood or lower for industrial waste-to give you the best end product for whatever you run through it. Available setup options from 20 to 40 hammers and counter knives give you multiple alternatives to find the right mix of speed, fuel economy, and output quality to best fit your needs.

• Low operating costs: The Barracuda's single rotor and bolt-on hammer inserts for reduced maintenance times, the internal rotor gearbox with high torque for greater fuel efficiency and large hydraulic reservoir for lower operating temperatures all play a part with the many other key features to reduce operating costs in this new design - all to increase your bottom line!

To get the first look at the Barracuda, visit Morbark in the Silver Lot at CONEXPO in booth #3491.

About Morbark:

Morbark, Inc., based in Winn, Mich., builds equipment that creates opportunities in the forestry, recycling, sawmill, bio-energy and tree care markets. Innovating and manufacturing durable, high-performance equipment for more than 50 years, Morbark offers a full line of whole tree and waste wood chippers, flails, brush chippers, horizontal and tub grinders, sawmill equipment, material handling systems and more. Morbark equipment helps customers harvest, process and convert wood and organic waste materials into valuable, useful and environmentally sound products.

.gif)