LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleGreat Lakes Manufacturing is proud to announce that CJ Logging Equipment, based in Boonville, New York, has joined the Great Lakes team as a stocking dealer. Craig French, Great Lakes founder and owner stated that the combination of CJ Logging Equipment’s four locations in Boonville and Little Valley, New York, Allenwood, Pennsylvania and Wheelock, Vermont plus their proven commitment to providing superior customer service were the main reasons he selected them to represent Great Lakes line of top quality steel and aluminum trailers.

CJ Logging Equipment will soon be stocking the complete line of Great Lakes products including both crib and bunk log trailers, pup and knuckleboom trailers, truck racks and the revolutionary new Raptor High Strength Steel log bunks available on new trailers and to retrofit those with inferior or worn out bunks. Loggers and Log Haulers in the Northeast can depend on CJ Logging Equipment. Their state of the art in-house and road service, honest and professional sales team, coupled with a complete line of timber harvesting equipment make CJ the only call needed for all your logging and trucking needs.

For complete details on Great Lakes Manufacturing’s line up visit www.greatlakesmfg.com or call 1 920-842-2012 in the Northeast US call CJ Logging Equipment at 1-800-541-4214 today.

Following months of extensive design, development and testing, Brute Force Manufacturing unveiled the new Auto Cycle box wedge firewood splitter at the NYS Logger Field Days in Boonville, New York. Versatile is the word to describe this new splitting system that features a 26.5 HP Kohler gas engine, powerful 5” splitting cylinder, hydraulically controlled wedge, conveyor and block lift that can be attached on either side to fit your firewood splitting operation and is available with or without the hydraulically controlled conveyor.

Built the BRUTE FORCE WAY, the Auto Cycle features a 2-stage 48 gallon per minute hydraulic pump with built in hydraulic cooler, large 7 gallon fuel tank and heavy duty laminated main beam with replaceable wear plates for extended service life. The key feature of the Auto Cycle is the fact that once engaged the cylinder will cycle hands free, allowing the operator to position blocks for peak production. Providing amazing versatility, the super wide box wedge easily handles blocks up to 48” in diameter. The box wedge produces uniform finished wood that is ideal for stove use, retail, package and specialty restaurant woods. Plus, with optional 4 or 6 way standard wedges, the Auto Cycle converts to a high production standard wood splitter in minutes.

The new Auto Cycle, like every Brute Force firewood processor, lives up to their company slogan “INVEST LESS – PRODUCE MORE”. For complete details on this and other quality firewood production, packaging and handling machinery visit www.bruteforcemfg.com or call 715-678-0037.

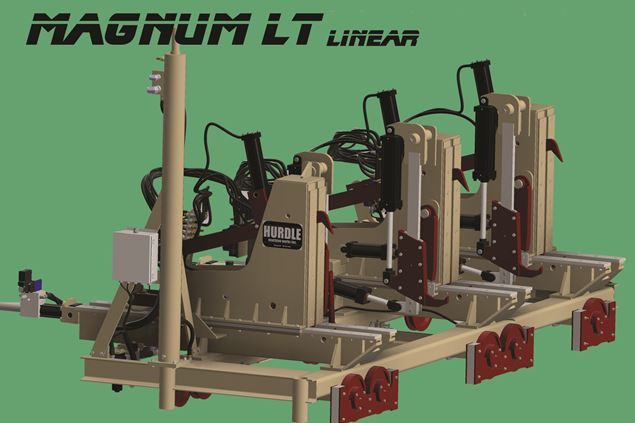

Hurdle Machine Works Inc introduces the Magnum LT Linear carriage, the latest addition to the Magnum carriage line which has successfully been in production for the last 10 years.

With 40" knee openings and 29" dog openings the carriage is the perfect size for today's hardwood mills. The first carriage went out in May and is operating in a 6 foot double cut bandmill running Lewis Controls setworks. Along with a Hurdle Resaw the mill is cranking out 50,000+ bd/ft per day of grade lumber. Superior engineering focused on simple design in an 8000 to 12000lb package with multiple options make this a smart investment. Parts are stocked for immediate shipment. However, the design is simple and there aren't many parts to worry about.

Videos of the new linear carriage can be found at www.youtube.com/hurdlemachineworks.

Morbark, LLC, is proud to introduce the powerful, mid-size Rayco C275 Forestry Mulcher.

"Rayco sets the bar for high-performance equipment built with the operator in mind," said J.R. Bowling, Rayco Manufacturing Mulcher Specialist, "and this model is no exception."

C275 Forestry Mulcher

Perfect for clearing small trees, underbrush, and a variety of unwanted vegetation across a wide range of environments, the C275 delivers 275 horsepower (205 kW) in a compact, low ground pressure package.

The C275’s 109-gpm cutter system provides hydraulic power to the Predator mulcher head, which boasts a 77.5-inch (196 cm) cutting width, while the heavy-duty steel undercarriage and powerful final drives allow operators to tackle difficult terrain with confidence. The C275 also will accept a DENIS CIMAF mulcher head.

Rayco’s exclusive elevated cooling design keeps engine and hydraulic temperatures within their limits in even the harshest of environments. To minimize maintenance, an operator can activate a reversing fan from the cab to clear the debris screens, helping extend service intervals even when operating in hot, debris-filled environments. The debris screens are easily removable when manual cleaning becomes necessary, and the rear door opens to allow unrestricted access to the debris screen and engine radiator.

The cabs are climate controlled and sealed from dust and debris to maintain operator comfort. Operators appreciate the high-backed, heated seat with adjustable armrests and air-ride suspension. For safety, the cab is certified to meet ROPS, FOPS, and OPS specifications and is equipped with a rooftop escape hatch. High-output LED work lights and a backup camera enhances rearward visibility.

"The C275 packs the power necessary for larger-scale clearing into a compact and agile unit," said Bowling.

Other key features include Rayco’s exclusive track tensioning system with monitor, which alerts the operator to over-tension situations and provides easier access to track tension grease fittings; hydraulic tilt cab to access pumps and other components easily; and the hydraulic rear winch.

With the growing demand for high-quality finished wood slabs in the woodworking industry, Wood-Mizer introduces the SlabMizer MB200 Slab Flattener ideal for sawmill owners, woodworkers, and professional workshops. Built in the USA, the SlabMizer efficiently surfaces and flattens wood slabs, boards, burls, cookies, and other wide material with minimal labor.

Compared to a traditional router or planer, the SlabMizer flattens wider and thicker material up to 56” wide and 8” thick in less time using powered cutter head directional controls with variable feed speed. For larger capacity, 5’ modular table extensions can be added to extend the material length and a 72” width option is coming soon. With the addition of the SlabMizer, Wood-Mizer offers wood processing equipment from forest to final form that can turn a log into a kiln-dried, finished wood product.

SlabMizer Features:

• Starting at $16,995 USD

• 56" max material width and 8” max thickness

• 13' material length or longer with 5' modular table extensions

• Powered cutter head directional controls with variable feed speed or manual feed

• 5,500 RPM 5” cutter head with five 4-sided carbide knives

• Orbital sanding head attachment for fine finishes

• Built in the USA

“Wood-Mizer is committed to providing our customers with the equipment necessary to process material from forest to final form,” said Greg Bacon Sales Director. “The SlabMizer satisfies the needs of operations producing high-value finished slabs and reduces the manual labor required to finish these wide slabs that are extremely valuable in the woodworking industry.”

Starting at $16,995 USD, the SlabMizer is now available to order in North America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Shiocton, Wisconsin – Go Fast Manufacturing is excited to announce the release of the newest addition to their impressive line of pallet notchers. The new “Twin NXL” notcher is the Go Fast machine designed to focus on the middle tier of today’s pallet makers and specialty sawmills. The “Twin NXL” is a heavyduty double head pneumatic manual notcher designed to fill the gap between today's entry-level single head pneumatic notchers and high-end, high-production, and expensive, auto-feed double head notchers.

“This new notcher represents the next generation of Go Fast’s notchers,” said Go Fast President, Dan Berken. “Our desire is to fill the needs of pallet makers looking for a middle-tier notcher that is high quality, powerful, compact, and reasonably priced. This notcher addresses a gap in the market that has gone unfilled for far too long. Now, our smaller and mid-sized customers can move towards becoming more competitive notching powerhouses. All at a reasonable cost while allowing our customers to realize the benefits of greatly improved productivity and profitability.”

Compact and sturdily constructed, the new “Twin NXL” is a highly capable double head notcher. The machines features:

• Unlimited Length Capacities Available

• Custom Height Options

• Custom Cutter Widths and Profile Options

• Safe and Simple Operation - Dual Safety Hand Controls, Pop-Up Safety Gates Never Expose Cutters

• Quad Clamping System - Over 1,200 lbs Of Clamping Force

• Twin 20HP Baldor Motors

• Heavy-Duty 3/8” Steel Framing - Built for Years of Trouble-Free Use

• Dual 8” Outlets For Blower Connections – No Dust Collection Required

• Indexable Replaceable Tip Cutters - Nailbuster® Heads Available

• Notch New or Recycled, Even Full Cants - Cycles Up to 1,750 Stringers per Hour

• Adjustable Notch - Precision Adjustable with a Simple Crank Turn

Go Fast Manufacturing, LLC – Go Fast is a high quality, innovative, value-added manufacturer, of highspeed sawmill and pallet machinery. Go Fasts primary mission is to provide our customers with a mix of quality machinery, quality service, and a pathway to business success. With a growing selection of over 20 machine categories encompassing hundreds of options and configurations, Go Fast is rapidly becoming one of the premier suppliers to the industry. They manufacture machines that are, “Go Fast Built To Go Fast!”

LaGrange, GA – Weiler Forestry, Inc. is pleased to announce the launch of Weiler purpose-built forestry products.

The purpose-built forestry product line consists of Wheel Skidders, Track Feller Bunchers, Wheel Feller Bunchers, and Knuckleboom Loaders. Weiler Forestry facilities include the manufacturing plant and warehouse in LaGrange, Georgia, the demonstration and training center in Auburn, Alabama, the Prentice engineering and product development center in Prentice, Wisconsin, and the legacy Prentice parts distribution center in Smithfield, North Carolina.

Founded in 2000, Weiler currently produces an extensive portfolio of paving products and has a long history of successfully manufacturing purpose-built equipment distributed through the Cat dealer network.

“Over the past several months, we have been listening to forestry customers and dealer personnel. We are excited to implement product expansion plans quickly to better serve the forestry market,” said, Pat Weiler, owner and founder of Weiler, Inc.

“I am looking forward to continuing to listen to our customers so we can offer them the products that best serve their needs through the best dealer network in the world.” commented Bill Hood, VP of Weiler, Inc.

Weiler Forestry will design and manufacture purpose-built forestry products, which will continue to be available through the Cat dealer network, providing customers with the same outstanding sales and service support they’ve come to expect.

Sawmill Supplies & Equipment, LLC of Sarepta, LA is proud to unveil its new website, created by the LumbermenOnline.com team! The new website allows for customers to quickly find equipment that fits their needs in an easy to browse, mobile design. Perspective customers can easily find options, general specs, videos and large, clean pictures of equipment to make their equipment search easier.

Sawmill Supplies & Equipment LLC is owned and operated by the Morgan family, which brings three generations of experience, innovation, and high standards to their equipment line up, including the Original Low-Profile Band Resaw. Holding this branding as a long-standing staple in the industry is a continued focus for Sawmill Supplies and is explained throughout the new website. Equipment made by the Morgan’s has always been simple in design, easy to operate and maintain, and saves you big on labor – the new website follows right in line!

If you’re looking for the Original Low Profile Band Resaw, Multi-Head Resaws, Trim Saws, Notchers, Dedusters, Edgers and MORE - Check out the new www.SawmillSupplies.net!

August 18, 2019 – Dorchester, WI – Following months of extensive design, development and testing Brute Force Manufacturing unveiled the new CS20-24HD circular saw firewood processor at the NYS Logger Field Days in Boonville, New York to rave reviews. Buyers at the show were impressed with the CS20-24HD’s extremely fast cutting and cycle times, putting it in the same class as machines requiring nearly double the investment. Featuring a low maintenance replaceable tipped 48 inch carbide circular saw, improved feed tray design and sturdy rigid frame to providing long service life. The CS20-24HD is powered by a fuel efficient Kohler 74HP Tier 4 liquid cooled diesel engine, that includes a 3 year manufacturer’s warranty and provides superior power for maximum production. Available with your choice of 4, 6 or 8 way wedge, it was exhibited at the Boonville event with the new optional box wedge designed to produce smaller uniform wood that is ideal for stove use, retail, package and specialty restaurant woods.

The CS20-24HD, like every Brute Force firewood processor lives up to their company slogan “INVEST LESS – PRODUCE MORE”. For complete details on this and other quality firewood production, packaging and handling machinery visit www.bruteforcemfg.com or call 715-678-0037.

Wood-Mizer introduces the LX250 wide slab sawmill designed for sawyers and woodworkers that need to saw massive slabs and boards up to 54 ½” wide. Joining Wood-Mizer’s world-leading range of portable sawmills, the LX250 is the second largest capacity sawmill offered by the company, with the popular WM1000 sawmill capable of sawing 67” diameter logs.

Built in the USA, the LX250 is a robust sawmill with powered saw head controls for ease of operation, adjustable presets for quick and accurate blade height control, and a massive 54 ½” width of cut ideal for sawing wide, live edge slabs.

A key innovation of the Wood-Mizer LX sawmill series includes the rigid LX Frame sawhead tower that holds the control panel, engine, and the sawmill head. Designed to accommodate a larger width and depth of cut, the LX Frame travels on twin parallel hardened steel rails on the bed and allows the operator to have better visibility while sawing.

LX250 Wide Slab Sawmill Features

• Starting at $25,995 USD

• 55” log diameter with 54 ½” max width of cut and 13' length of cut

• Optional 5’ bed extension available for 18’ max length of cut

• Powered saw head up/down & forward/reverse with dual power feed chain system

• Adjustable preset board thicknesses to quickly and accurately control blade height

• 38HP gas engine or 15HP 3-Phase electric motor

• Built in the USA

“Wood-Mizer is dedicated to providing best-in-class sawmill and wood processing equipment that fits the diverse needs of our customers,” said Greg Bacon Sales Director. “With the growing demand of wide, live edge slabs and boards, the LX250 provides customers a large capacity sawmill at an affordable price that can efficiently produce these high-value wood products.”

Starting at $25,995 USD, the LX250 Wide Slab Sawmill is now available to order in North America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

CHATTANOOGA, Tenn., July 29, 2019 — Komatsu America Corp., a leading global heavy equipment manufacturer, recently launched its new XT-5 Series of Track Feller Bunchers. Models include the XT430-5 (non-leveling), XT445L-5 and XT465L-5, which replace the prior XT-3 Series machines.

The XT-5 Series ranges in operating weight from 66,359 lb. (30,100 kg) to 74,516 lb. (33,800 kg) and features a new, more powerful fuel-efficient EPA Tier 4 Final engine, gull-wing style engine hood, increased lift capacity, heavy-duty undercarriage, redesigned and relocated cab, new hydraulic and cooling systems, forestry-specific guarding and KOMTRAX® telematics system technology.

“We have been systematically gathering and analyzing voice-of-the-customer input to define our next generation of feller bunchers,” said Mitsuhiro Utsumi, vice president, forestry product marketing, Komatsu America. “This new XT-5 Series represents the culmination of translating that entire input into feller bunchers which truly meet the needs of today’s demanding loggers,” Utsumi said.

Performance & Productivity

The new 310 peak hp (231 kW), Cummins QSL9 9-liter engine provides more horsepower, torque and displacement and lowers fuel consumption by as much as 10%, due to advanced engine and hydraulic system control designs. Lift capacities at full reach lift have been significantly increased, and the XT465L-5 now readily operates the Quadco 24-inch (610 mm) cutting capacity disc saw heads.

Operator Comfort & Convenience

The state-of-the-art, fully-certified, Komatsu forestry cab has been relocated to the left of the boom for industry commonality. Cab design changes provide superior lines-of-sight to each track. A standard rearview monitoring system further enhances the operator’s view. Eleven (11) LED lights provide superior visibility for night operations.

Komatsu’s highly intuitive, IQAN-MD4 digital control system programming allows up to three (3) different operators to program their individual control patterns for increased multi-operator productivity. An IQANsync mobile phone app is available to allow remote access to perform IQAN system functions.

Reliability & Durability

New more rugged Komatsu undercarriages significantly increase service life including:

• Rugged, 8.5" track chain links are stronger at resisting "twist"

• Track rollers and idler bushings are made of high-density material allowing longer wear

• The XT445L-5 and XT465L-5 have larger track guard roller side openings to minimize mud packing and facilitate cleaning

• The XT465L-5 has 9 vs. 8 rollers for improved load distribution. Track length has been extended to the rear by 5.3” (135 mm) for improved steep slope stability

• The XT445L-5 and XT465L-5 have a reduced track slider angle producing 30% lower contact pressure for reduced wear

• All final drives have a new triple labyrinth floating seal housing to protect the seal against mud packing

Larger capacity, hydraulic piston pumps for the implement, attachment and disc saw operate at 500 rpm lower speed, while delivering high performance flow. Each pump has a pre-charged (pressurized) suction inlet to reduce cavitation risk. A robust forestry-specific guarding system covers the boom, arm and rear hydraulic tubes and hoses to provide superior protection and shed debris.

The totally new high capacity cooling system features a large radiator, charge air cooler and hydraulic cooler. All coolers have been relocated to the rear of the machine to minimize debris buildup. Separate radiator and hydraulic oil cooler fan controls provide the cooling needed to maintain the required temperatures. Both fans have an auto-reversing function to help purge debris and maintain cooling efficiencies.

Ease of Maintenance

A new gull-wing style engine hood folds down to provide an elevated service work platform. Four (4) other service doors swing wide to provide excellent service access. An innovative new hydraulic tank design features two (2) tanks, which require 55% less total hydraulic oil (a refill requires only 45 gallons = 171L). The attachment control valve has been relocated from the main control valve to the arm for ease of service.

Komatsu’s exclusive KOMTRAX remote equipment monitoring and management telematics system is standard. It utilizes highly reliable, satellite-based technology to transmit valuable information such as location, utilization and maintenance records to a PC via an internet website. KOMTRAX provides advanced machine troubleshooting capabilities by monitoring machine health and issues caution and abnormality alerts. This information serves as a valuable tool for scheduling preventative maintenance and service. There is no subscription fee for the life of the machine.

Komatsu America Corp. is a U.S. subsidiary of Komatsu Ltd., the world’s second largest manufacturer and supplier of earth-moving equipment, consisting of construction, mining and compact construction equipment. Komatsu America also serves forklift and forestry markets. Through its distributor network, Komatsu offers a state-of-the-art parts and service program to support its equipment. Komatsu has proudly provided high-quality reliable products for nearly a century. Visit www.komatsuforest.us and www.komatsuamerica.com for more information.

Irma, Wisconsin - Firewood Automation president, Don Liebelt, announced recently that Firewood Automation has become the new Hakki Pilke distributor and dealer for the upper Midwest region, including Wisconsin and adjoining states with expansion opportunities both west and south. Hakki Pilke is one of the world’s leading manufacturers of high quality, compact, low cost and profitable firewood processing and handling machinery. The addition of Hakki Pilke will augment Firewood Automation’s product line providing firewood splitters and processors for the homeowners and ranchers, specialty producers and high volume professionals alike.

For sales, service, parts or to inquire about dealer opportunities within the upper Midwest region Firewood Automation is your connection for Hakki Pilke Products! For more information, call Firewood Automation at 715-360-6292 or visit www.Firewood-Automation.com.

.gif)